Folding Kayak - PVC Skin

Attachment

All kinds of coamings - wood and fiberglass - be attached with Velcro on the inside edge of the coaming. The inside Velcro connection is more watertight than the foam seal used with the HDPE coaming / baseplate. This also allows use of the coaming without a base plate, though a temporary base plate is used for construction only.

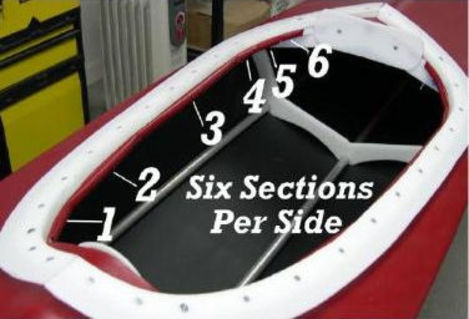

Due to it's narrow profile, the wood coaming is free standing and uses no machine screw connections as are used with the HDPE and fiberglass coamings. With it's wider profile, the fiberglass coaming can be connected to cross sections 4 and 5 with stainless steel machine screws. The use of machine screw attachments allow more rigidity along the deckridge.

Split Coaming

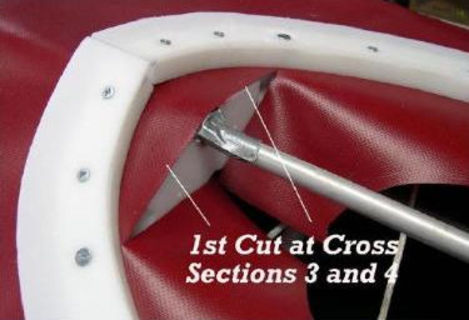

The skin is

attached to the coaming base plate with Velcro. The PVC inside the

coaming is cut open to allow access to the hold down machine screws

attaching the base plate to cross sections 3 and 4. (Symetrik). Remove

the skin around the machine screws (4 ea.) to allow access.

Attach the

coaming to the base plate with 4 machine screws. Once attached, trim the

PVC to within 3 inches of the inside edge of the coaming. This material

will fold around the base plate for Velcro attachment.

Cut the PVC along cross section 3 and 4 between the coaming inside edges.

Cut the skin

in sections small enough to easily conform to the shape of the coaming

edge. Trim the folded under sections to the width of the base plate.

Cut Velcro strips to approximately 3/4" X 2" and glue to the skin. Cover the entire base plate with a strip of Velcro.

Baseplate - Be sure the HDPE baseplate is clean and dry. Using the

adhesive backing provided with the Velcro, attach to the baseplate.

Skin - Velcro adhesive doesn't adhere well to PVC, so the adhesive

backing and PVC must first be prepped with MEK. Dry completely and

apply 2 - 3 coats of HH-66 to the skin and the Velcro adhesive backing.

After drying, apply heat and pressure to insure a good bond.

After

attaching Velcro to the skin and base plate, the skin is tucked under

the coaming base plate and attached to the opposite Velcro strip. If

needed, heat can be applied to the Velcro of the baseplate or skin for

removal and replacement.

One Piece Coaming

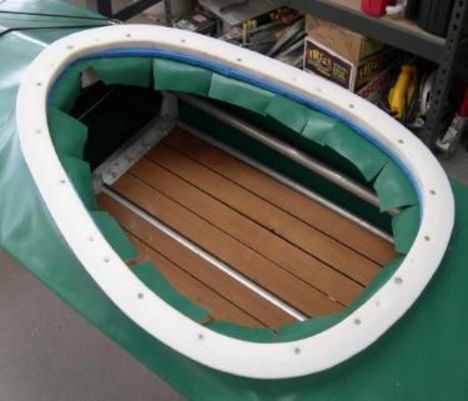

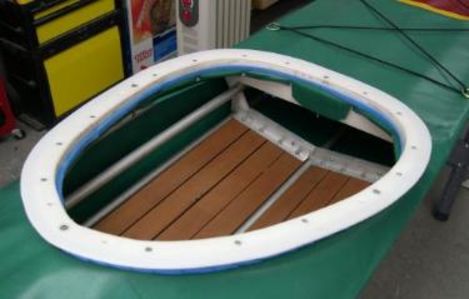

The one piece coaming base plate with 2" wide Velcro fitted and trimmed.

PVC is cut

into 2" - 3" inch strips to allow wrapping the skin under the base

plate. Velcro will be glued to each section and tucked under the plate

for attachment. Four small holes are cut in the skin to allow machine

screw access.

The 22" X 16" Coaming. Machine screws (4ea) connect to the base plate. All other screws secure lip to coaming.

The PVC skin

is Velcro'd to bottom of the base plate. A 1/2" foam seal is glued to

the bottom of the coaming, and the coaming is bolted to the base plate.